Impressed Current Cathodic Protection (ICCP) Systems

ICCP SYSTEM

Impressed Current Cathodic Protection (ICCP) Systems

Smart, Long-Term Defense Against Corrosion

Impressed Current Cathodic Protection (ICCP) systems are the advanced, long-lasting solution to marine corrosion, offering a superior alternative to traditional sacrificial anode systems that require frequent replacements. Designed for durability and efficiency, ICCP systems are increasingly favored by shipowners for their ability to lower fuel consumption, reduce maintenance costs, and extend vessel lifespan.

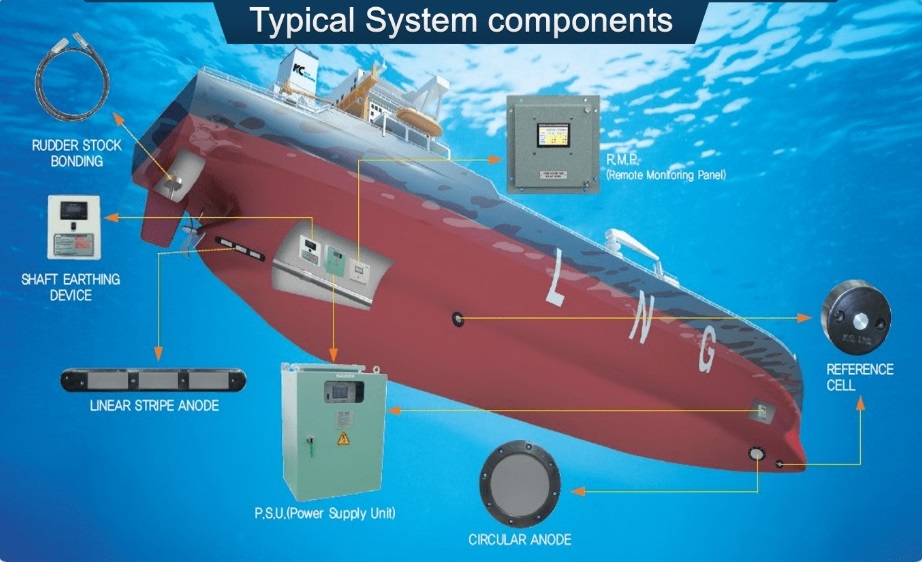

Century 365’s ICCP systems operate by delivering a carefully regulated DC current to submerged metal surfaces, effectively neutralizing the electrochemical process that causes galvanic corrosion. This current is continuously monitored and controlled by the system itself, ensuring consistent, automated protection. We utilize high-performance mixed metal oxide (MMO) anodes and zinc reference electrodes to ensure accuracy, reliability, and long-term operation in harsh marine environments.

For over 25 years, ICCP technology has been trusted by vessels of all types and sizes — including oil tankers, LNG carriers, cruise ships, naval craft, superyachts, offshore platforms, and workboats — delivering 24/7 corrosion protection against the damaging effects of electrolysis in saltwater conditions.

With Century 365, you gain a proven defence system that keeps your hull protected, your costs down, and your fleet sailing strong.

System Advantages of ICCP Technology

Extended Lifespan of Underwater Components

Provides long-term protection for rudders, shafts, struts, propellers, and all submerged metallic parts exposed to electrolysis.

Compact, Durable Anodes

Lightweight and robust anodes ensure easy handling, storage, and installation — ideal for vessels of all sizes.

Adaptive Protection in All Conditions

Anodes, reference electrodes, and automatic control systems work together to deliver precise corrosion protection, adjusting in real time to changes in salinity, temperature, or coating condition, unlike fixed-output zinc anodes.

Fully Automated System Operation

Integrated control units maintain optimal current flow, allowing for simple, reliable, and maintenance-light performance.

Cost-Efficient, Documented Corrosion Control

Delivers superior protection at a lower lifetime cost through minimized maintenance, fewer replacements, and improved hull efficiency.

One-Time Installation for Long-Term Protection

Designed to last the life of the vessel or marine structure, eliminating the need for repeated dry-dock installations.

Extended Dry-Dock Intervals

By significantly reducing corrosion-related damage, the system contributes to longer intervals between dry-docking — saving time and operational expense.

EXPLORE

Advanced ICCP Systems Engineered for 20+ Years of Protection

Our ICCP System is designed for our worldwide clients with the following features.

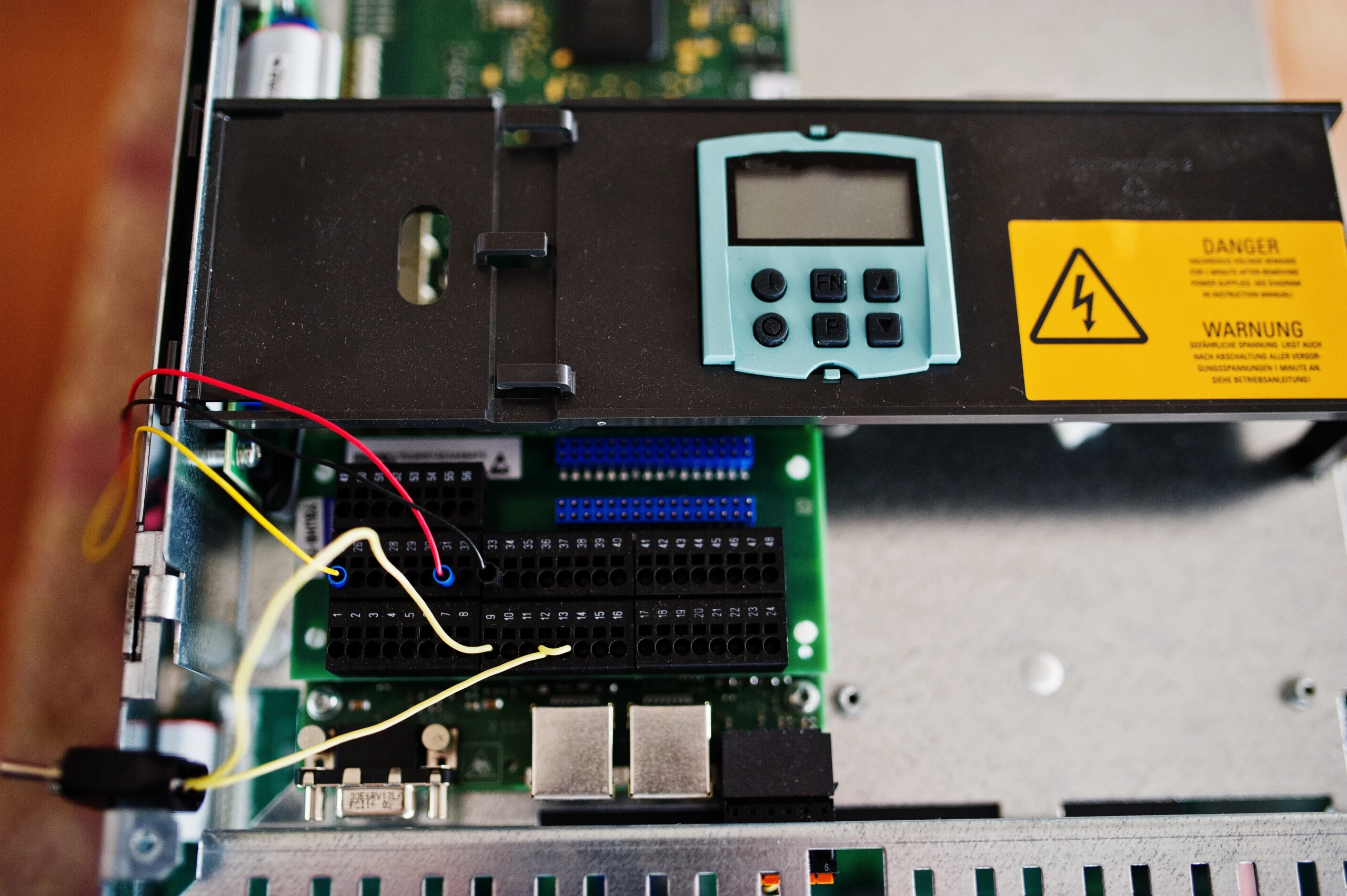

- Auto/Manual mode

- 4.3” TFT Touch screen LCD display

- Data download is applicable through a USB memory

- Wastewater Treatment Systems – very convenient operation with an easy and sophisticated controller.

- Data communication and alarm signals can be connected to the ship’s AMS

- Simple installation in all kinds of new buildings as well as retrofitting ships.

ICCP system

Reference Cell / Electrode

ICCP systems are controlled to assure optimum protection. This control is obtained by inserting a third electrode between the anode and the cathode. The third cell/electrode is insulated and does not receive any anode current. This cell/electrode is freely corroding and it becomes the starting point — or reference — in eliminating corrosion. Cell/Electrodes constructed of Zinc are used exclusively with the ICCP system.

ICCP system

Reference Cell / Electrode

ICCP systems are controlled to assure optimum protection. This control is obtained by inserting a third electrode between the anode and the cathode. The third cell/electrode is insulated and does not receive any anode current. This cell/electrode is freely corroding and it becomes the starting point — or reference — in eliminating corrosion. Cell/Electrodes constructed of Zinc are used exclusively with the ICCP system.

ICCP system

Power Supply Unit / Control Panel

Each standard ICCP system utilizes a solid-state controller that monitors and controls the protection as measured by the Zinc Reference electrode. Anode current automatically increases when the electrode potential falls below the designated control value. An over- and under - potential alarm is provided with the system package. We also offer optional digital control, state-of-the-art technology with every system. The computer controller shown below is more accurate and provides central control, monitoring, data storage, and hard printout.

ICCP system

Mixed Metal Oxide Anodes

Mixed Metal Oxide anodes of are used exclusively for ICCP systems. ICCP anodes are manufactured in Linear Loop, Elliptical and Circular designs with insulating holders. They are available in a single unit capacity of 75 to 225 amperes, as required for various installations.

Century 365

Our Partners

Meet our valued partners who contribute to our commitment to quality and professional service.

Associate reginal partner

Cathodic Marin Engineering Co is the associate partner company for Century in the Southeast Asia. Providing excellent Cathodic engineering services to the Marine industries in this region.

Their commitment to quality, innovation, and industry standards strengthens Century’s ability to deliver trusted engineering services across Southeast Asia.